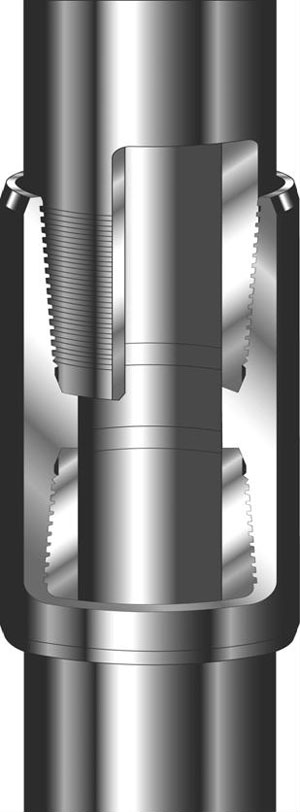

VAM HW ST

VAM HW ST is a rugged T&C connection for heavy wall casing when maximum tension strength is required. It is especially suited for surface casing and production casing in High Pressure High Temperature wells.

BENEFITS

- Excellent gas-tight sealing

- Extra high strength

- Low hoop stress

- Easy to use and repair

VAM Metal Seal and Reverse Angle Torque Shoulder

- A 50% taper metal-to-metal seal is energized by a reverse angle torque shoulder, and is self energized by internal pressure.

- The rugged design of the pin nose makes this connection able to withstand the high combined loads that are encountered in deep, high pressure wells.

- VAM HW ST is the solution for a connection to withstand pressures as high as the burst and the collapse ratings of the heavy wall casing.

Hook Thread Design

- A coarse thread pitch with a 3° reverse load flank angle gives the connection superior tension strength and eliminates the risk of jump out.

- Precision machining in the threads contributes to reduce hoop stresses in the coupling.

- A steep thread taper allows for easy stabbing and fast make-up. Making-up heavy wall casing with VAM HW ST is as easy as with standard wall casing, with virtually no danger of cross threading.

Extra Strength Coupling

- The coupling size is calculated to provide in excess of 100% tensile efficiency on heavy weight casing.

- The coupling design minimizes hoop stresses, and is ideal for use with controlled yield materials in High Pressure High Temperature wells where sour gas or other corrosive environments may be encountered.

Streamlined Internal profile

- The I.D. is recess-free, with 6° mating chamfers at the end of the long coupling shoulder. This smooth bore allows the safe running of tools and minimizes turbulence and energy loss when high velocity gas flows are encountered.

Options

- VAM HW ST SC70 and SC80 (Special clearance): for extra clearance applications, as when annular space is a limiting factor.